Products

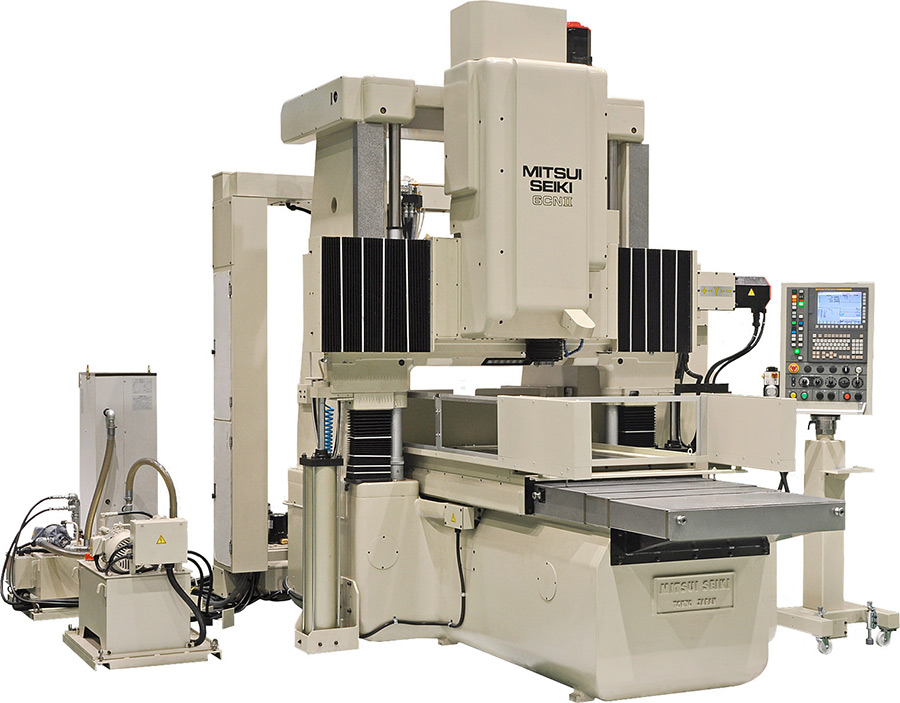

MODEL J6CN WITH FANUC 30iM-B

SPECIFICATIONS AND STANDARD FEATURES

MITSUI SEIKI High Precision Jig Boring Machine Model J6CN with Ultra-precision accuracy for operations that demand jig boring tolerances. Provided with Integrated circuit logic, closed loop, complete electrical equipment for operation on 3-phases 50/60Hz, 200/220 Volts AC.

MACHINE SPECIFICATIONS

| Working Range | |

| Table longitudinal travel (X axis) | 1020mm (40") |

| Saddle table transversal travel ( Y axis) | 760mm (30") |

| Quill vertical travel (Z axis) | 300mm (11.81") |

| Cross rail vertical travel (W axis) | 750mm (29.5") |

| Cross rail vertical travel (W axis) with optional ATC | 700mm (27.5") |

| Distance between columns | 1120mm (44") |

| Max. distance from table surface to grinding spindle nose | 950mm (37.5") |

| Work Table | |

| Work surface | 1280 x 960 mm ( 50 x 38") |

| Nos. of T slots | 8 on 106 mm pitch |

| Rapid feed | 5,080 mm/min. (200 ipm) |

| Fine feed | 0.1 - 2,000 mm/min. (80 ipm) |

| Permissible load table | 1200kg (2,700 lb.) |

| Spindle Saddle | |

| Rapid feed | 5,080 mm/min. (200 ipm) |

| Fine feed | 0.1 - 2,000 mm/min. (80 ipm) |

| Cross Rail | |

| Speed of cross rail elevating | 560 mm/min. (22 ipm) |

| Clamp / unclamp | Automatic |

| Balance |

2 Sets Air Cylinders with auto pressure regulators |

| Quill | |

| Quill diameter | 125mm - 5" ,(145mm - 5.7" at nose) |

| Rapid feed | 3050mm/min (120 ipm) |

| Cutting feed | 0.1 - 2,000 mm/min. (0.004 ~ 80 ipm) |

| Working Capacity | |

| Drilling capacity | 60 mm Ø (2.36" Ø) |

| Boring capacity | 300 mm Ø (11.8" Ø) |

| Max. face milling cutter diameter | 150 mm Ø (5.9" Ø) |

| Minimum Resolution of X,Y and Z axies | 0.001 mm (0.000039) |

| Spindle Drive Motor | |

| Spindle Motor Specifications |

AC 7.5/5.5kw (Cont/30 Min Rating) (10hp / 7.3hp - Cont. / 30 min) |

| Power required | |

| Electrical Service Required |

AC 220 Volt , 3 phase, 80 amp (60 Hz) 26 KVA |

| Air required | |

| Air Service Required |

6 kg/cm2 (0.59Mpa) or more (90psi) 300NL/min (11 cfm) |

| Machine dimensions | |

| Length | 3,790 mm (150" Approx) |

| Width | 2,700 mm (107" Approx.) |

| Height Max. (Min.) | 3,685 (2,935) mm (145" / 115") |

| Distance from floor to table surface | 940 mm (37") |

| Weight | 9,000 kg 19,800) |

| Floor Space (Including peripheral equipment and maintenance area) |

|

| Length | 5,800mm (19') |

| Width | 5,180mm (17') |

| Height | 4,575mm (15') |

| CNC Unit | |

| CNC Control | Fanuc 30iM-B |